Fimap Maxima Scrubber Dryer

The Worlds Best Scrubber Dryer For Small & Medium Spaces

When you need your floors immaculate and the mop and bucket simply wont do, our Fimap Genie Scrubber Range is the perfect choice for any type of hard floor surface.

Choose from 3 models for a complete solution, the Fimap Genie E, is a mains powered scrubber dryer together with the Fimap Genie B, cordless battery versions. Both are great for cleaning hard floors where little debris is present with a selection of brushes and pads for any type of surface. You can strip floors, deep clean floors and polish floors with ease.

When tackling uneven floors and floors presented with debris, the Fimap Genie Bs is the ideal choice. Fitted with roller (cylindrical) twin brushes, this machine collects light debris into a tray directly behind the brushes, elimiating streaky floors and blockages for easy cleaning and peak performance on every clean.

MAIN BENEFITS

- 50 cm Single & 60cm Twin scrub decks with pad holder & brush options

- 50 cm Cylindrical Scrub Decks with sweep & scrub action

- 50 cm Orbital Square Scrub Deck with heavy duty cleaning action

- Basic, Plus & Pro Mode for total control of your cleaning tasks

- Fleet Management System for remote control and diagnostics

If your looking for a quality floor cleaner to make your cleaning operation efficient, why not book a free on-site demonstration, and see what the Maxima Scrubber Dryer can do to enhance your floors.

If you need help choosing the best scrubber dryer, our team are here to help.

Call us on 01942 466258 or complete our enquiry form.

TECHNICAL SPECIFICATIONS

MAXIMA KEY BENEFITS

Disc brushes are the most versatile type of brush head, that can adapt to any type of environment and surface. The scrubbing machine with disc brushes can be used on any hard floor, easily removing even stubborn dirt thanks to the adjustable pressure. In models with one disc brush, the detergent solution emerges from the center of the brush, ensuring even cleaning with reduced water consumption. In models with two brushes on the other hand, it’s FWF – Fimap Water Flow technology that guarantees an even distribution of the water on both brushes, avoiding any waste of water and detergent.

The cylindrical brush head consists of two counter-rotating cylindrical brushes that not only scrub but also make a light sweeping action. The sweeping action removes small, solid, non-adherent residue and collects it in a drawer installed at the rear of the brush head, which is removable for emptying. This type of brush head is recommended for hard floors (even structured, uneven or non-slip).

The bristles clean deep down, guaranteeing optimum results even where there are wide gaps. Given the high specific pressure and the notable rotation speed, it’s more suited to resistant floors not protected with a polymer film (wax). The counter-rotating movement keeps the detergent solution inside the scrubbing area, increasing efficacy yet ensuring low water consumption.

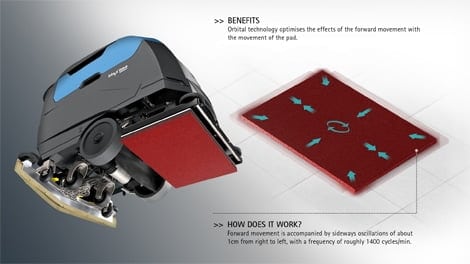

The brush head consists of a rectangular pad that oscillates crosswise in relation to the direction of machine movement. The orbital movement ensures excellent, uniform results across the entire surface as every point of the pad is in constant contact with the floor. This type of brush head is ideal when working on structured floors or those with wide gaps.

The efficacy of the mechanical action, combined with the use of abrasive pads, minimizes the use of detergents, in particular the most aggressive ones rich in VOC (volatile components).

A basic, simple panel with graphic instructions for a quick start-up. A digital indicator shows the battery charge level and the working hours.

The frame, brush head and squeegee mount and body are made of aluminum. This material ensures robustness and resistance to corrosion for the internal structure. In addition, it’s a lightweight material so it doesn’t affect the weight of the machine, which is therefore maneuverable and easy to transport.

Parts which must be cleaned regularly at the end of every shift are color-coded in yellow. This is a very simple solution that reminds the operator how to carry out correct machine maintenance.

In this way, constant excellent performance is guaranteed over time, and malfunctions are reduced.